| 型号 |

Model |

DDDD |

| 装箱速度 |

Encasing speed |

x箱/分钟 box/min(视纸箱大小而定) |

| 纸盒 |

Box |

质量要求

尺寸范围 |

250-350g/m2

()x()x()mm |

| 压缩空气 |

Compressed air |

工作压力

耗气量 |

>=0.6mpa

20m3/h |

电源

主电机功率 |

Power supply

Motor dimension |

220V/380V 50HZ

xkw |

总功率

外形尺寸 |

Total power

Machine dimension(LxWxH) |

xkw

X x X x Xmm |

| 整机净重 |

Machine weight |

Xkg |

Note: If the user has special specifications, We can design and manufacture according to customer’s special needs.

Optional:can seamlessly integrate with other packaging equipment such as three-dimensional packaging machines, cartoning machines, strapping machines, and heat shrink packaging machines, forming a complete packaging production line.

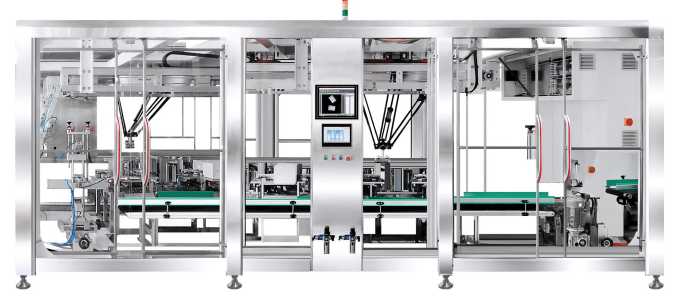

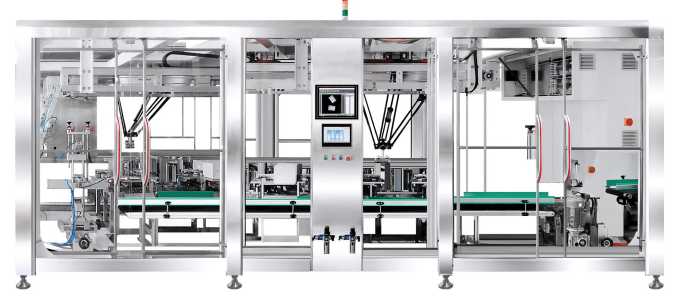

The unpacking, packing, and sealing machine is suitable for the packing of regularly shaped products such as food, daily necessities, pharmaceuticals, and electronics. It integrates the functions of unpacking, packing, and sealing into one unit, significantly reducing the machine's footprint and achieving multi-use with a single machine.

1.Can be adjusted according to different product specifications and packaging needs, adapting to handle various sizes of cartons.

2.Utilizes a programmable PLC control system and a human-machine interface to display the operating status of the equipment, faults, alarms, and finished product counts.

3.Integrates the functions of unpacking, packing, and sealing into one unit, reducing transitional steps between equipment and enhancing production efficiency.

4.Employs servo modules with multiple stroke unpacking actions to ensure stable and reliable carton opening.

5.According to different product needs, we can choose the robot grasp, spider hand and other grasping materials to meet the production requirements.

6.Can seamlessly integrate with other packaging equipment (such as three-dimensional packaging machines, strapping machines, heat shrink machines, etc.), forming a complete packaging production line.

7.Occupies less space, which is beneficial for optimizing workshop layout.

8.Ensures stable performance and simple, convenient operation.